Delivering Freshly Cooked Aroma to the Table with Aroma Volatility Control Technology

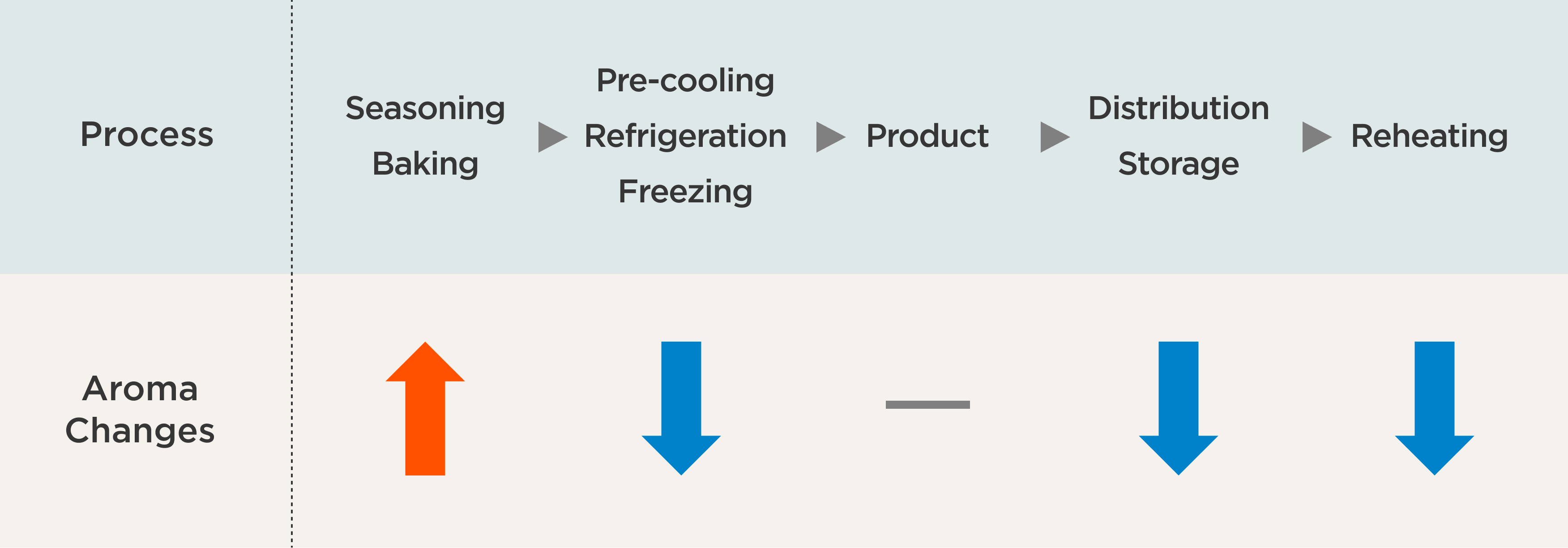

Aroma is a key factor that determines the deliciousness of food, along with taste and texture. However, in processed foods, aroma significantly diminishes in the time between manufacturing and reaching our customers. This occurs because many aroma components are highly volatile, and temperature changes during various processes - from heating and cooling during manufacturing through distribution, storage, and reheating - cause these components to evaporate or decompose.

Changes in Aroma in Processed Foods (Example)

To address this, we developed aroma control technology designed to adapt to these temperature changes, establishing an aroma enhancement technique that delivers the freshly cooked, delicious aroma to our customers. Named the "Umami-Enhancing Aroma UP Method," this technology is now applied across various Nissui food products.

Research Approach

To establish this technology, we first used Gas Chromatography Mass Spectrometry (GC/MS) together with Sniffing Gas Chromatography to identify the aroma components associated with "the just-prepared freshness and flavor" in various foods. Next, we analyzed specifically which steps showed the greatest decrease in these components during the process from manufacturing to consumption using GC/MS. Based on these results, we tested various materials and methods to determine the optimal conditions for retaining aroma. During screening, we confirmed aroma component quantities using GC/MS and also quantified human sensory perception through direct sensory testing.

Figure 2. Identifying aroma components (sniffing gas chromatograph)

The "Umami-Enhancing Aroma UP Method" focuses on oils and emulsifiers to suppress aroma volatilization. We discovered that many aroma components dissolve easily in oil, and that the presence of oil helps suppress their volatilization. To effectively capture aroma components within the oil, we investigated oil types and stirring/mixing conditions to determine optimal parameters. Furthermore, we found that using emulsifiers enhanced the ability of oil to retain specific aroma components. Through these methods, we succeeded in maintaining fresh-cooked aroma.

Research Results

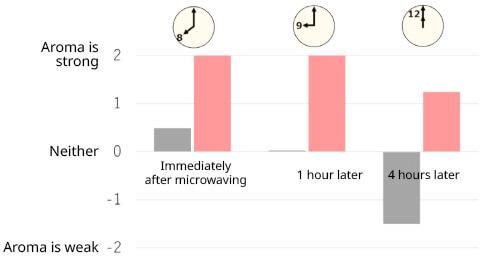

After establishing this aroma enhancement technology to deliver a "freshly cooked, delicious aroma" to customers, we registered the patent (No. 6490289) in 2019. For example, this technology is used in our "Wakadori no Tatsuta-age," which retains its freshly cooked aroma even hours after microwaving, making it ideal for boxed lunches.

Figure 3. "Kyou no Okazu Wakadori no Tatsuta-age" Using Aroma Technology

Figure 4. Changes in aroma strength over time after microwave heating

Furthermore, aroma components also influence taste. For instance, a stronger soy sauce aroma can enhance the perceived saltiness of food, making this technology useful for developing reduced-sodium products. Through this technology, we have successfully created various products that use fewer seasonings, enabling us to offer health benefits to customers by reducing sodium.