We are creating new value from marine resources by building a global supply chain of marine products that covers everything from fishery, aquaculture and production to processing and sales.

Business Overview

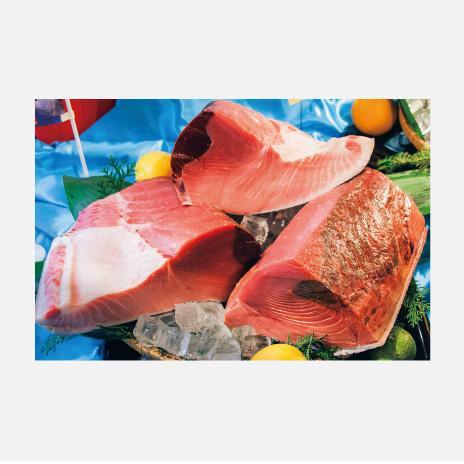

We access marine resources through fisheries and aquaculture. Beyond selling frozen and fresh fish as raw materials, we are advancing initiatives to create easy-to-use food ingredients for a wide range of customers through our processing technology and product development capabilities cultivated over the years.

As global demand for marine products continues to grow, aquaculture plays an increasingly important role in supplementing limited natural marine resources. The Nissui Group operates aquaculture of Japanese amberjack, salmon and other species in Japan, while also producing and selling formula feed for farmed fish.

Business Strengths

- Access to global marine resources

- Global supply chain covering procurement, processing and sales

- Differentiated aquaculture technology including selective breeding

Business Areas & Group Companies

Fishery

In Japan, Kyowa Fishery Co., Ltd engages in inshore purse seine fishing.

Kyowa Fishery Co., Ltd (Japan)

Aquaculture

The Nissui Group cultivates Japanese amberjack and coho salmon, Pacific bluefin tuna, greater amberjack and other species in Japan. For some species, we conduct "full-life cycle aquaculture" where we raise fish from eggs produced by our own farmed fish rather than capturing wild juveniles, aiming for sustainable aquaculture operations. We also produce and sell formula feed for farmed fish.

Kurose Suisan Co., Ltd. (Japan)

Yumigahama Suisan Kaisha,Ltd. (Japan)

Nissui Maguro Co., Ltd. (Japan)

Processing/Sales

In Japan, we procure and sell fresh and frozen fish and manufacture and sell highly-processed marine foods.

Nissui Corporation (Japan)

Business Initiatives

Advancement of Aquaculture Business

Amid increasing global demand for marine products, aquaculture plays an increasingly important role in supplementing limited natural resources. In the Nissui Group's Japanese amberjack aquaculture, we implement selective breeding - selecting fish with superior traits to raise as parents for the next generation - and have achieved full-life cycle aquaculture. Full-life cycle aquaculture, which does not use wild juveniles (mojako), is a sustainable initiative that reduces pressure on limited marine resources. To expand aquaculture scale and improve productivity, we are engaged in large-scale offshore aquaculture while developing and implementing various aquaculture technologies through collaboration with other companies.

Anticipating that sea-surface areas suited to aquaculture will reach saturation in the future, we are also conducting feasibility studies on land-based aquaculture. Nissui has positioned aquaculture as one of its future growth strategies and is strengthening its business foundations accordingly.